Powder Coating & Sand Blasting

Powder coating is the application of a dry paint in the form of a powder onto a surface using the principle of electrostatic charging. Powder may be a thermoplastic or a thermoset polymer. It is usually used to create a hard finish that is tougher than conventional paint. After the application process the paint is cured under heat to allow it to flow and form a “skin”.

Before applying the finish, the chosen part must either chemically or mechanically cleaned, removing dirt, oils, old, finishes, and oxidation. Poor surface preparation results in powder coating problems, which is because of impurities and poor adhesion between the powder and the metal base.

Our solutions range from initial planning through to procurement, construction management, and commissioning & operational support services. By combining our facilities from engineering, design and detailing through fabrication, erection and quality testing, we deliver fully integrated project management services matching international standards.

Powder Coating

- Our company specializes in providing powder coating services, a durable coating method applied as a free-flowing, dry powder. Unlike traditional liquid paint, which relies on evaporating solvents, powder coating is applied electrostatically and then cured under heat or ultraviolet light. This results in a resilient finish that lasts longer and offers superior protection against wear and tear. With our powder coating services, you can expect high-quality finishes that withstand the test of time, ensuring your products maintain their appearance and durability over an extended period.

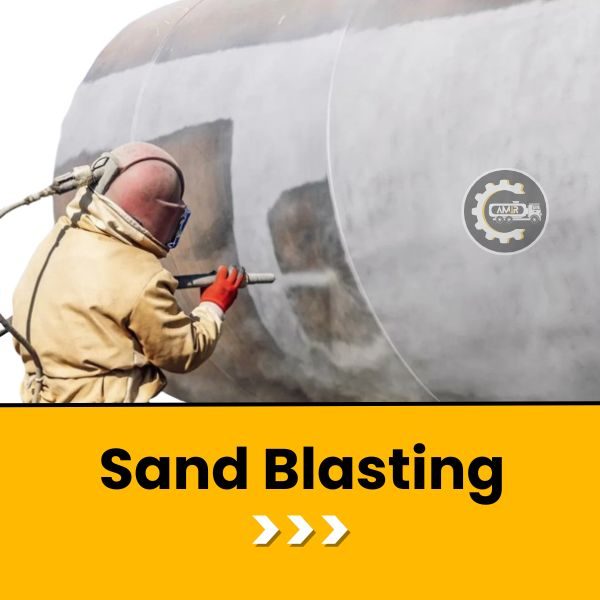

Sand Blasting

- Our company specializes in providing sandblasting services, also known as abrasive blasting, a process where a stream of abrasive material is propelled against a surface under high pressure. This technique is used to smooth rough surfaces, roughen smooth surfaces, shape surfaces, or remove surface contaminants effectively. Utilizing heavy-duty sandblasting machines, we ensure precise and accurate sandblasting, resulting in quality finishes and optimal surface preparation for various applications. With our expertise in sandblasting, we strive to deliver superior results, meeting the requirements and expectations of our clients.